- alu@haomeicn.com

- +86 135 9841 7520

Aluminum pp cap sheet's greatest qualities are drawability and lacquer adhesion, guaranteeing the highest quality printing of drawings and designs. The most common alloy for closures is 8011 alloy, which has good formability, good earring rate and flatness, so as to make sure the long cap deep drawing. It often used as ROPP caps for wine bottles, and other beverage bottles.

8011 Aluminium sheet is used for the bottle cap market. Using a unique rolling technology, Haomei supplies aluminium sheets ideally suited to manufacture the caps for long neck wine bottles, extremely deep drawn and decorated closures, plus a range of pilfer proof caps for beverage bottles, soft drink, juice, isotonic beverage, energy beverage, and other products, such as the 30x60 mm specifications are often used in the wine and spirits segment.

Best class formability, flatness, rectangularity and unwavering surface properties.

Stable deep drawing quality to make sure highest rates of materials rate.

Various processes and technologies can meet the requirements of various surfaces.

| Alloy | 8011 |

| Temper | H14, H16, H44, H46 |

| Thickness | 0.2-0.25mm |

| Width | 500-1000mm |

| Length | 500-1000mm |

| Alloy | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

| Each | Total | |||||||||||

| 8011 | 0.60~1.0 | 0.50~0.9 | 0.1 | 0.2 | 0.05 | 0.05 | 0.1 | - | 0.08 | 0.05 | 0.15 | Remain |

Alloy |

Temper |

Thickness (mm) |

U.T.S (Mpa) |

Elongation (%) |

8011 |

H14 |

0.15~0.25 |

185~205 |

≧2 |

| Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) |

| 8011 | H14 | 0.15~0.25 | 125~155 | ≧2 |

Plain mill finish

DOS oil lubricated finish

Chromated finish

One side golden/white/red/blue/black, etc., other side protective lacquered

both sides clear/transparent lacquered

Typical closure application: Ropp caps, PP cap, roll on pilfer proof cap, aluminum pilfer-proof cap, pilfer proof closure, aluminum bottle cap, aluminum screw cap, tear off caps, flip off caps..

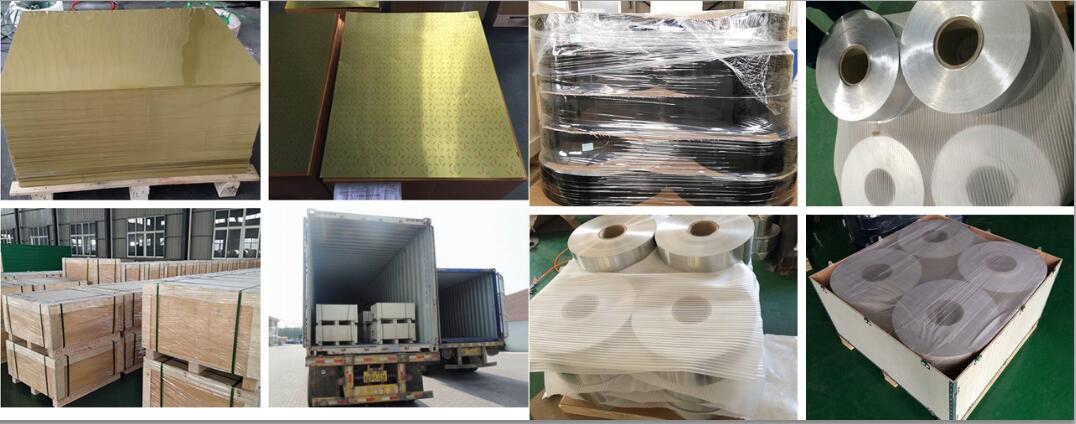

The basic packing method is clamps, but we can also provide packaging according to your needs.