- alu@haomeicn.com

- +86 135 9841 7520

Alloy 5052 is an aluminium–magnesium alloy, primarily alloyed with magnesium and chromium. 5052 is not a heat treatable aluminum alloy, but can be hardened through cold working.

Aluminium alloy 5052 contains nominally 2.5% magnesium & 0.25% chromium. It has good workability, medium static strength, high fatigue strength, good weldability, and very good corrosion resistance, especially in marine atmospheres. It also has the low density and excellent thermal conductivity common to all aluminium alloys. It is commonly used in sheet, plate and tube form.

Specs of twist off lid sheet:

| Alloy | 5052 |

| Temper | H16/H14 /H19 |

| Thickness | 0.20-0.30mm |

| Length | 800-1000mm |

| Width | 800mm -1000mm |

| Packing | Wooden case, wooden pallet if request. |

Size and deviations from the size

| Thickness tolerance | -0+0.5mm |

| Width tolerance | -0+0.5mm |

| Length tolerance | -0+0.5mm |

Deviations of the forms/shapes:

| Deviations of the straight for hardness of the longitudinal border | max 1mm |

| Deviation of flatness | max 4mm |

| Rectangularity: max difference in the diagonals | 3mm |

| Dislocation between the sheets | max 2mm |

Surface of the sheets

Available Surface types

Mechanical data:

| Resistance to stretching Rm | Min 180 Mpa Max 220 Mpa |

| Yield strength Rpop | Min 145Mpa |

| Elongation | Min 2% |

1. Both sides clear epoxy varnish

2. One side clear epoxy varnish, the other side color coated.

Clear lacquer Aluminum foil sheet Coating thickness:

Golden color /yellow color: both sides coating 5-6g/m2, one side coating 2-3g/m2.

White/red/black/blue color: Both sides coating 10-13g/m2.

Boiling Resistant: Boiling 121 degrees for half an hour, the paint does not fall off, do not change color.

Resistance to acetone and mercuric chloride: repeatedly wiping 20 times without significant stripping

Typical closure application: Aluminum easy open ends, easy open can lid, easy open can parts, aluminum ring pull.

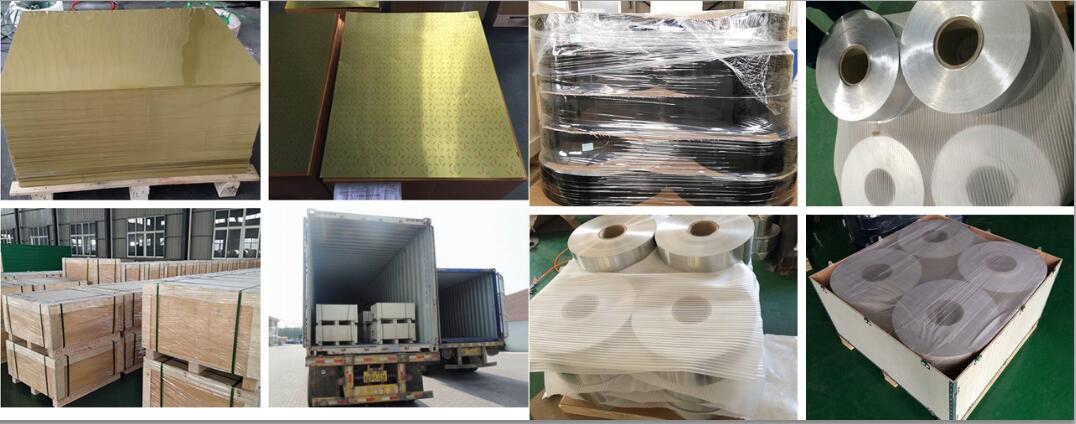

To ensure that the surface of the 5052 aluminum sheet/plate is intact without scratches, we will clamp paper and cover film on the 5182 aluminum sheet/plate.

The plastic or kraft paper package is used for moisture-proof and rainproof to ensure that the 5052 aluminum plate is clean and free from dirt during transportation.

We add wooden support and reinforce it with a steel belt to avoid collision during transportation and ensure the shape of the 5052 aluminum plate is unchanged;

Export products are all packaged in wooden cases and brackets marked with fumigation.