- alu@haomeicn.com

- +86 135 9841 7520

Aluminium PP cap Sheet closure stock material consists of Aluminium sheets and coil for manufacturing of ROPP caps or closures or caps for bottles.These are available in various alloys, temper, thickness, custom made sizes and are suitable for long and short draw.Custom sizes, thickness and sheets sizes are made as per specifications and requirements of customer.

We are the leading provider of Aluminum PP Cap Sheet .These products are identified amid patrons for their noticeable features such as longer life, durability and nominal cost.

We provide closure sheet materials to meet customer needs for closures that protect a container's contents, open easily and are highly convenient.

The main four aluminum PP Cap Sheets are 1060, 5052, 3015 and 8011 aluminum alloy.

Haomei aluminium supplies Aluminium PP Caps Sheet and coils for the manufacture of bottle closures. Applications range from screw caps for whiskey and other beverage bottles to aluminum closures for wine bottles. ROPP cap material can be ordered as rolled, degreased, pre-lubed, pre-treated and / or lacquered.

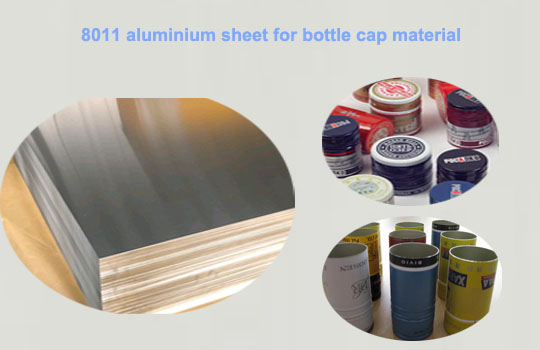

8011 Aluminum is an ideal material for PP Caps of whiskey bottles and other beverage bottles.8011 alloy sheet is of light weight, superior barrier property and good formability.

3105 aluminum alloy for screw caps has sufficient strength and can withstand large gas pressure. It is widely used to make screw caps for soda bottles, such as soda water and carbonated wine.

8011 aluminum strip injection vial seals, is also used for pull-off aluminum caps. In addition, 8011 H16 alloy according to EN573-3 can also be used to make omnia jar cap.

5182 aluminum alloy can lid material is mainly used for making ring-pull can/ring-pull can/ring-pull can and pull rings of all green pull cans and tin cans.5182 aluminum alloy is the main alloy for pulling ring material.

5052 Aluminum is optimal for sheet metal work and is very easy to form at room temperature.5052 aluminium bottle closure sheet has low density, light weight, smooth surface, good feel, flexible deformation after stamping, and is not easy to crack.

For 1060 aluminium strip has very good ductility and processability. Its production and processing technology is relatively mature on the market, and it is easier to obtain.1060 aluminium strip foil for injection vial seals in many countries and regions are very common.

aluminum 1070 O cosmetic cap stock is ideal for use on perfume bottles and cosmetic bottles, which need shining and bright surface, such as cream jar, cosmetic cap etc.

Aluminum closure sheet's greatest qualities are drawability and lacquer adhesion, guaranteeing the highest quality printing of drawings and designs.

Aluminum Closure Coil is a new type of bottle cap sealing material, which not only has the characteristics of beautiful appearance, but also has the function of preventing counterfeit goods. .

Haomei Aluminium pp cap Sheetss are suitable for both transparent and non-transparent lacquering, and will not bend during curing process. For applications requiring deep drawing, such as long caps, Haomei Aluminium pp cap Sheets show very low earing, greatly reducing scrap rate for our clients.

Haomei Aluminium pp cap Sheet is rolled to very fine tolerances to yield more closure per tonne of stock and to allow uninterrupted operation of high-speed, multiple-cavity presses. Its strength, high formability, low earring and printable surfaces make it ideal for pilfer-proof caps and vial seals.

Chemical composition and rolling reduction and temperature can be adjusted to achieve higher material strength, allowing the sheet gauge to be reduced (making them lighter).

We control material composition, rolling temperature and time, and annealing temperature to produce optimal materials to meet clients’ performance needs, such as its opening capability and earing.

If requested, we treat materials with phosphoric acid chromate or zirconium to improve paint adherence.

We carefully monitor flatness and squareness to prevent color gapping, unevenness or print misalignment during printing.

| Alloys | Applications | Characteristics |

|---|---|---|

| 3105 | General-purpose materials | Formability is good, and strength can be standardized to meet product demands. |

| 8011 | Closure stock material | ROPP cap, PP cap, roll on pilfer proof cap, aluminum pilfer-proof cap, pilfer proof closure, aluminum bottle cap, aluminum screw cap, tear off caps, flip off caps. |

|

|

|

Known as a “size coat,” foundation processing is conducted to help the paint adhere better. Products that are processed using phosphoric acid chromate or zirconium are often cut. |

|---|---|

|

Either the public side or the product side surface may be painted first, depending on the product. |

|

The number of printing passes depends on the image to be printed on the cap. |

|

Glossy varnish. |

|

A single slitter method is used to cut the sheet into three equal strips. For some products, both edges are trimmed at this time. |

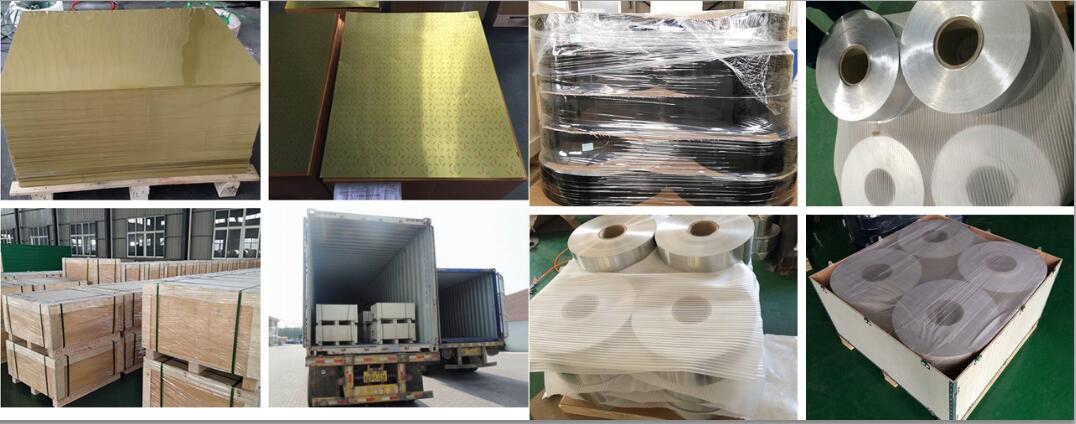

The basic packing method is clamps, but we can also provide packaging according to your needs.